The

Concrete

Fluid™ Concrete Technology use a custom composition of green cement combined with 95% recycled natural materials.

Our special moulding process incorporates multiple layers of structural meshing combined with a carefully mixed slurry to produce a high-quality and dimensionally stable concrete that is relatively lightweight and incredibly strong.

With a curing process that allows each piece to rest and set in controlled conditions, we are able to produce consistently beautiful products that are built to last.

Seamless Construction

We work with moulds capable of producing unibody products which are seamless, free from join lines, half the weight and twice the strength of common Portland concrete.

Environmental Resilience

Fluid™ concrete is resistant to water, fire, insects, termites, mould, and mildew.

Non-Toxic

Free from asbestos, formaldehyde, silica and carcinogenic materials, Fluid™ does not contain organic solvents, oils, toxic ingredients, heavy metal salts, or radiation.

Quality Control

Every piece is marked with a unique serial number for quality control purposes, is dimensionally stable with low expansion and contraction rates.

Lightweight

Sturdy yet lightweight composition makes it easy to move each piece from room to room.

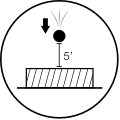

Impact Resistant

Our composite is so strong that dropping a 2.5lb [1.1kg] steel ball on to it from five feet above doesn’t cause any visible damage to the concrete.

Energy Efficient

Since no heat or pressure is used in the manufacturing process, 20-40% less energy is required to produce Fluid™ products compared to Portland cement- based products.

Durable

Our strong, robust concrete structures last longer than traditional composites, creating less waste and reduced need to repair or replace investment pieces.

Freeze and Thaw Resistant

Fully cured, non-hydraulic concrete does not retain water, meaning it is resistant to freezing and thawing. It also withstands extreme temperature fluctuations (air and liquid).

Low Carbon Emissions

Our green concrete composite produces 90% less pollutants compared to traditional Portland cement- energy during the manufacturing process.

Environmentally Friendly

Made from 95% recycled natural materials that absorb CO2 during the curing process, our composites are 100% recyclable and release minimal greenhouse gas emissions.

Testing Videos